Z-Arm 2140 Core Facts

±0.03mm

Repeatability

3Kg

Max payload

400mm

Reach

210mm

Z-axis

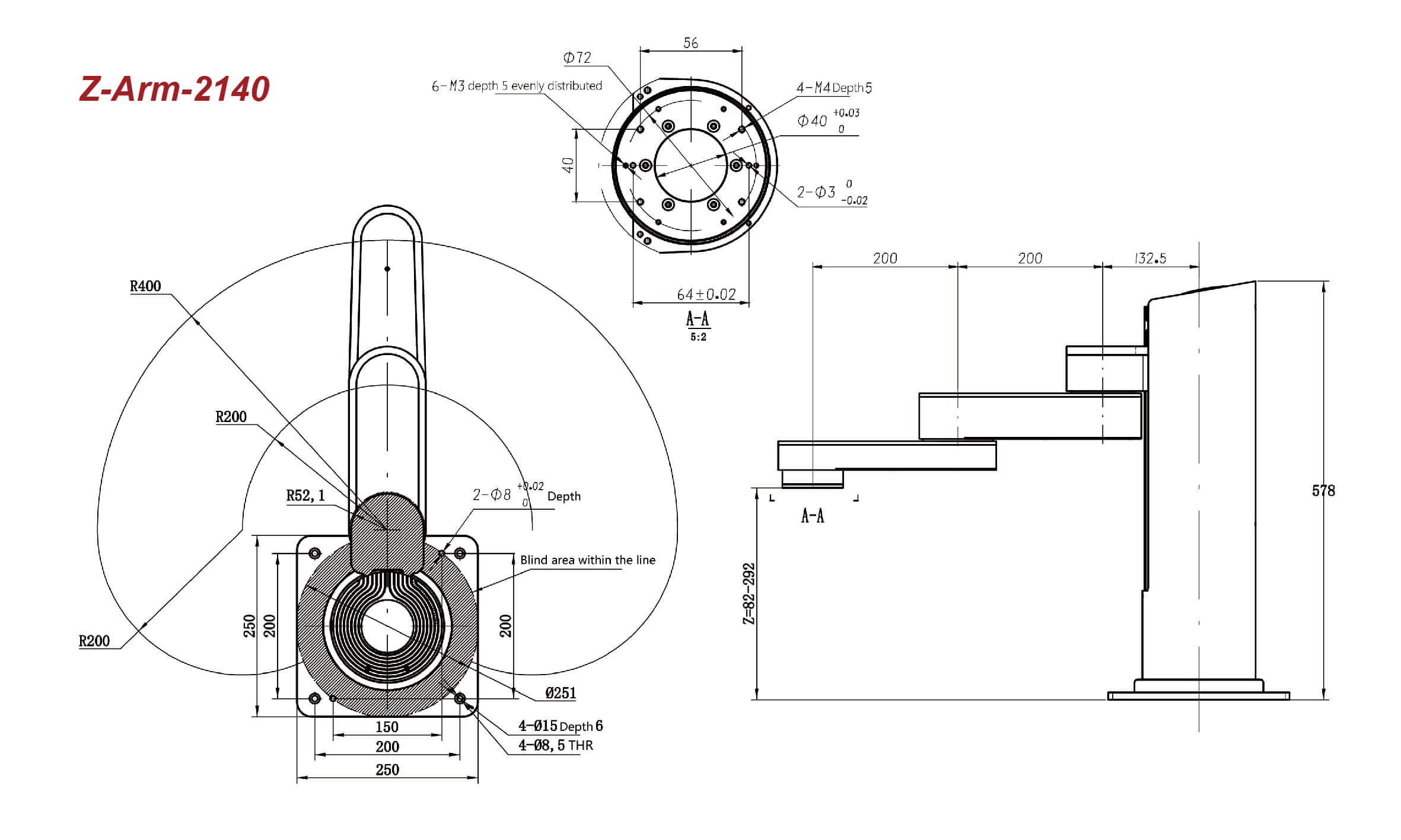

* Drawing

Product Features

Enhanced Payload Capacity

Comparing to its predecessors, Z-arm 2140 improves its payload capacity by 2 times, reaching up to 3KG. It will be a best contender for material handling and assembly tasks.

Safety and Stability

As a table-top collaborative robot, Hitbot Z-arm 2140 does pretty well in guaranteeing safety via collision detection and improving productivity by fast movement at 1255.45mm/s (with 1.5KG payload) and reliable repeatability of ±0.03mm.

Intelligent Programming

Hitbot Z-arm 2140 mainly can be easily set up in two methods. Users can utilize the self-developed one-stop APP HitbotStudio, or manually drag-and-drop the cobot itself to realizing machine teaching. Both only take about 20 minutes.

Open-sourced Hardware

Hitbot Z-arm 2140 is an open-sourced hardware cobot, which can be customized by customers themselves based on specific requirements. Supported programming languages includes V-rep, Ros, Matlab, Java, Paython and etc.

Various Optional Add-ons

With various optional end-tool kits, like electric grippers, the fifth axis kit, and Wi-Fi module, users can create unlimited application scenarios of future production right on the workbench.

Flexible Applications

Z-arm 2140 is ideal for a wide range of industries including the electronic, food and beverage, machinery, solar, pharmaceutical, medical and research sectors.

| Model | Z-arm 2140 | |

| Programming software | HitbotStudio | |

| Number of axis | 4 | |

| Rated payload | 2KG | |

| Maximum payload | 3KG | |

| Maximum reach | 400mm | |

| J1 reach(1st-axis) | 200mm | |

| J2 reach(2nd-axis) | 200mm | |

| J1 rotation (1st-axis) | ±90° | |

| J2 rotation (1st-axis) | ±164° | |

| Z-axis reach | 210mm | |

| Repeatability | ±0.03mm | |

| Connectivity | Wi-Fi/Ethernet | |

| I/O port | Digital input (isolated): 5 | Digital output (isolated): 5 |

| Collision detection | Supported | |

| Drag to teach | Supported | |