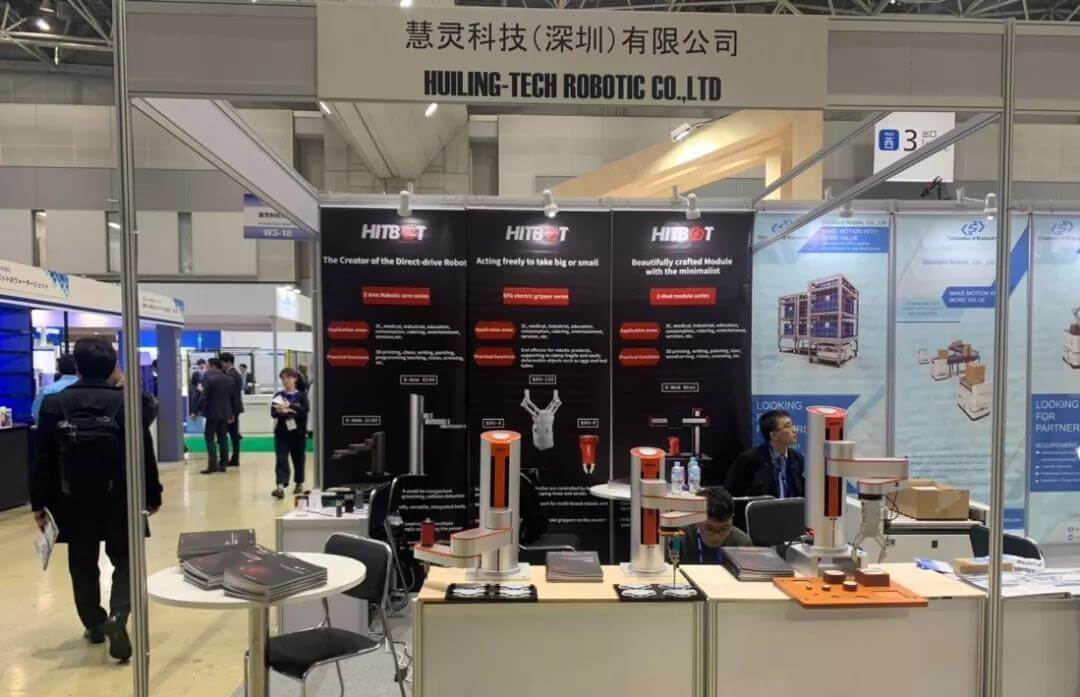

HITBOT Enjoyed 4-Day iREX Exhibition in Japan

Source:Hitbot Date:12.16.2019

During the recent week, HITBOT fully enjoyed the 4-day iREX Exhibition from Dec. 21St to Dec. 24th in Tokyo, Japan, with more business development with clients mainly from East Asia, treasuring opportunities of listening to customers.

The International Robot Exhibition (iREX) is One of the largest robot trade shows in the world, which saw participating exhibitors from 637 companies and organizations, with a total of 3060 booths, and attracted over 140,000 people visitors from 64 countries in 2019. Therefore, HITBOT enjoyed such a greatly valuable opportunity learning and exchanging robotics technology with other leading brands, and listening to customers’ opinions.

At the exhibition, HITBOT caught great attention from worldwide well-known brands such as Panasonic, Toshiba, LG, Hitachi, Foxconn, Wistron. it helped deepen the in-depth understanding of the needs of the Japanese market, and more clearly defined the upgrade and development direction of the future industrial chain.

With the rapid social development in recent years, the aging of the population has gradually become a problem not only faced by Japan but also the whole world. Human needs are increasing year by year, and labor costs are rising year by year, thus gradually bringing about many unmanned and automatic application scenarios, like unmanned convenience stores, automatic coffee kiosks, and automatic meal packaging service. In this way, robot arms are getting more and more important. The attendance of HITBOT at iREX provided a new choice of brand for customers when picking up a robot arm.

HITBOT broads rich experiences in providing industrial automation solution for clients from various sectors. Compared to other brands in the market, HITBOT is more cost-effective than other industrial-grade robot arms, and more reliable than other consumer-grade robot arms. When it comes to product quality, HITBOT has strong confidence to confirm the R&D capacity with dozens of patents and tens of certificates.

At present, HITBOT has successfully applied direct-drive technology to SCARA robot arm, saving about 50% of equipment costs, greatly reducing the threshold for the use of robotic arms; and improving labor efficiency by 50% by upgrading core components to enable human-machine collaboration. Undoubtedly, HITBOT will help more companies to complete the upgrade of automation equipment.

In the future, HITBOT will also continue to look at the world, deeply cultivate the industrial field, and create more miracles with cutting-edge robotic arm technology.